Arthur Harris products have set the industry standard in stainless steel components for industry applications where important qualities like strength, superior corrosion resistance, and buoyancy are required. The high-quality fabrication and attention to detail involved in the fabrication of Arthur Harris valve components like float connectors, make them the optimal choice for use in the process industry, as well as other industries that require flow management.

Arthur Harris products have set the industry standard in stainless steel components for industry applications where important qualities like strength, superior corrosion resistance, and buoyancy are required. The high-quality fabrication and attention to detail involved in the fabrication of Arthur Harris valve components like float connectors, make them the optimal choice for use in the process industry, as well as other industries that require flow management.

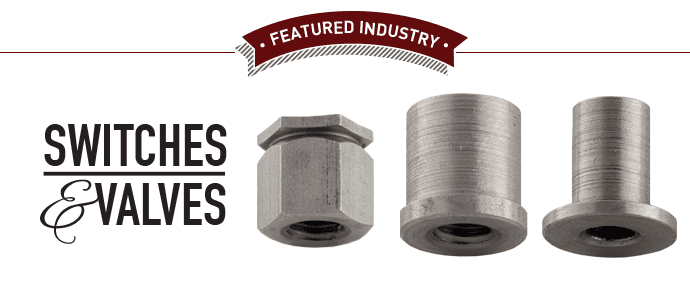

Float connectors are made from stainless steel, making them ideal for connecting stainless steel float valves or other devices in high-pressure conditions, at high temperatures, or submerged in water or corrosive liquids. Our stainless steel float valves are manufactured in 303 or 316 stainless steel and can be customized in multiple different threading configurations, making them highly versatile for unique applications. While a float valve is just a small component, they serve an important role by float valves in industries like oil and gas, chemical, and more.

Float Valves and Connectors at Work

A float valve, also commonly known as a ballcock, is a small mechanism used for regulating flow in tanks of liquid. Since float valves are used in numerous industries and applications, this could mean anything from a large vat of an industrial chemical to the water tank in a toilet. The purpose of float valves is to control the flow and fill level of the tanks, preventing overfilling, while the valve connector connects the valve to the incoming liquid. The valve is then opened or closed by the lever attached to the float when it rises to the selected level. All the components, the valve, float, and connector all work together to ensure that the liquid stays at the ideal level with minimal monitoring needed by technicians. For this reason, using only the highest quality components has never been more important.

Material Matters

Since float valves and their components like float balls and connectors are used in numerous industries with differing levels of temperature, pressure, and corrosivity, they need to be manufactured with a focus on durability, and there are no better materials for this than stainless steel. Stainless steel offers unmatched corrosion resistance, and components crafted with stainless steel do not have the same tendency to rust or deteriorate in harsh environments.

At Arthur Harris, we manufacture our extensive variety of floats and float valve connections using T303 and T316, two of the most trusted stainless steel alloys. Our connections (also known as spuds) can be used with any of the float shapes we offer, including custom threading options. With so many varieties available, it’s no surprise that our products are commonly used for liquid level control in every industry, from oil and gas to food processing.

Liquid Level Control in the Process Industry

Liquid level control is one of the most important factors in the safety and overall function of facilities in the process industries including gas and oil, chemical, and food processing. In these facilities, long lasting and corrosion resistant liquid level control devices like float balls, valves, and connectors are an integral part of safety and quality standards. Although each industry presents a different set of requirements, stainless steel can stand up to the varying levels temperature, pressure, corrosivity, and other factors that would contribute to the corrosion or oxidation of lesser alloys. This reliable strength allows engineers and technicians in these facilities to control liquid levels with confidence.

Order Float Valves and Connections From Arthur Harris

At Arthur Harris, we take pride in our ability to manufacture top quality liquid level control devices available on the market. We have years of experience designing custom liquid level and flow control components for the varying requirements of applications in process industries, and we’re always prepared for a new challenge. Just provide us with your requirements, including alloy, threading preference, connection or thread size, and quantity. Most of the items we produce are fabricated to our client’s specifications which can be sent to us in the form of blueprints. We look forward to designing the ideal device for your unique needs. Request a quote today!