Arthur Harris products have set the industry standard in stainless steel components for industry applications where important qualities like strength, superior corrosion resistance, and buoyancy are required. The high-quality fabrication and attention to detail involved in the fabrication of Arthur Harris valve components like float connectors, make them the optimal choice for use in the process industry, as well as other industries that require flow management.

Arthur Harris products have set the industry standard in stainless steel components for industry applications where important qualities like strength, superior corrosion resistance, and buoyancy are required. The high-quality fabrication and attention to detail involved in the fabrication of Arthur Harris valve components like float connectors, make them the optimal choice for use in the process industry, as well as other industries that require flow management.

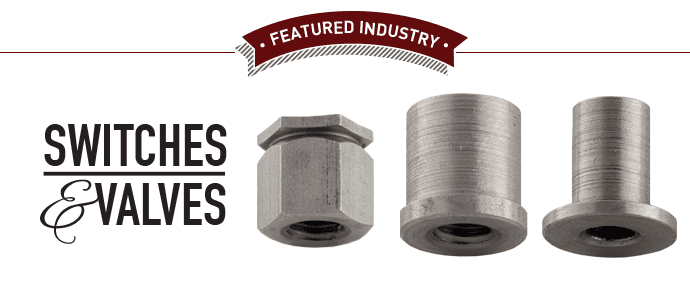

Float connectors are made from stainless steel, making them ideal for connecting stainless steel float valves or other devices in high-pressure conditions, at high temperatures, or submerged in water or corrosive liquids. Our stainless steel float valves are manufactured in 303 or 316 stainless steel and can be customized in multiple different threading configurations, making them highly versatile for unique applications. While a float valve is just a small component, they serve an important role by float valves in industries like oil and gas, chemical, and more. (more…)